Remote Virtual Inspections and Remote Visual Inspections at first glance appear to be involving the same type of specific technology. It is best to know precisely which is being referenced and what the benefits are, as well as how they may work in tandem on a project.

Remote Virtual Inspections refer to the use of common tools such as a computer, a mobile phone or tablet, and possibly headphones. This would be used by companies, state and federal governments to conduct a normal inspection of a constructed item such as a building, bridge or cell tower from a long distance. In other words, the person conducting the session is off-site, giving instructions to those at a job site using personal handheld devices like smartphones to record the information being tracked through the use of photos or video.

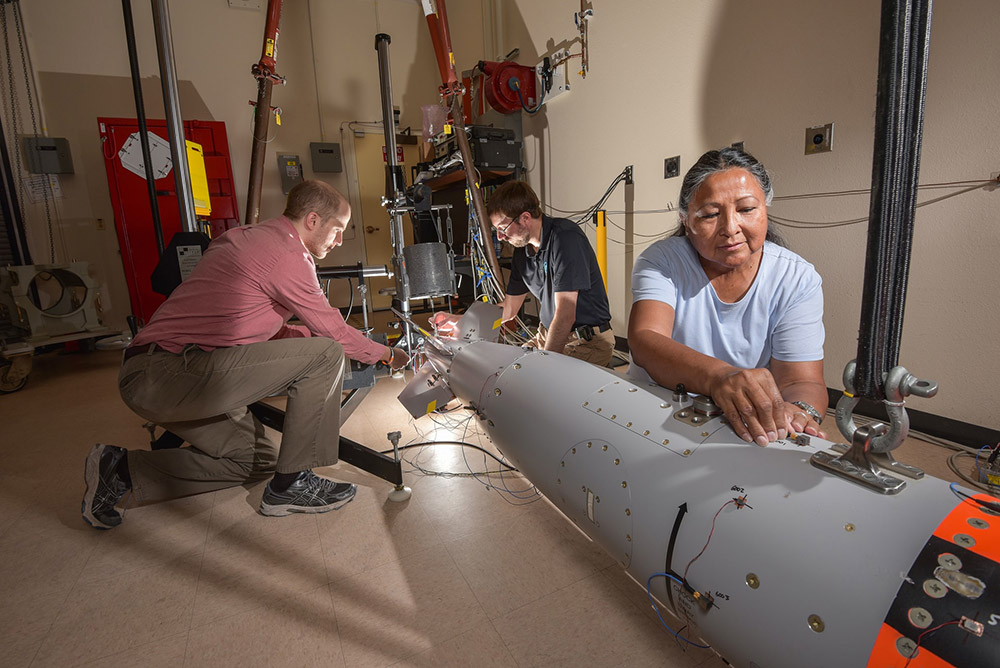

In a Remote Visual Inspection the person is usually onsite rather than off-site. That person may only be considered remote with respect to the specialized equipment used to view work sites in enclosed or typically inaccessible areas; for example, borescopes and video probes. These tools make a direct physical examination of the objects that would be difficult to view due to size, or perhaps danger. So a Remote Visual Inspection allows for non-destructive measures in the analysis of such devices. Remote Visual Inspections in this sense have been around since the 1970’s and at a minimum consists of a lens and a light source, which is extended through an extension piece where an eyepiece is attached. These have evolved into the modern borescopes used today.

Remote Visual Inspection and the Methods used to Perform One

One type of Remote Visual Inspection is a measurement based on comparisons. In this type of inspection a reference object is set in place and continuously compared with the object being scanned by a tool like a borescope. A second measurement type may be a stereo measurement, where a prism or similar device splits the image so that a left and right view can be captured and analyzed or measured using an algorithm. A final type is based on shadow triangulation to determine positioning and size of objects. Although less precise than the other methods, it can do an adequate job in measuring defects.

Remote Virtual Inspections, are on the other hand, most often used to provide the kind of visual inspections done by the naked eye. It is normally associated with video. The purpose of these inspections are to use a common communication device, the smartphone, as the eyes and ears of physical inspector who can give instructions from distances that can be many miles away.

How Methods Differ in Regard to the Job

Remote Visual Inspections are used on the areas that are not typically visible to the human eye. The Remote Virtual Inspection on the other hand can be used in place of a traditional inspection in most cases where a regulation does not require a licensed inspector to appear on-site.

Combining Remote Virtual and Remote Visual Inspection

Technological innovations have resulted in the integration of the tools used for Remote Visual Inspection and existing smartphones and tablets. Interfacing with modern phones will allow for Remote Virtual Inspection software to be able to engage in many inspection projects that were normally difficult to do off-site. CloudVisit’s Remote Inspection software is equipped to meet the needs of a variety of tasks for Remote Virtual Inspection. It has a feature set that can facilitate an inspection in big spaces, or within the crevices of a steel tank through device integration. Contact CloudVisit and schedule a demonstration to see how Remote Visual Inspection software can tackle any project.

Language:

Language: